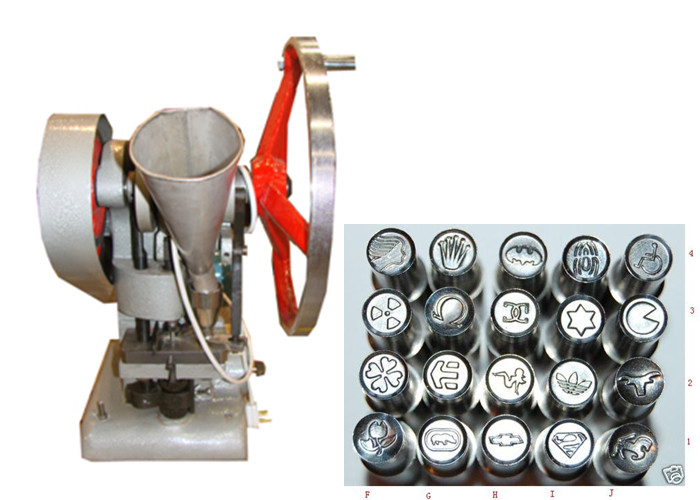

Tablets Accessories & Pills Accessories

Tablets Accessories and Pills Accessories:

Overall, the tablet is a substance made up of two types: one type is to serve as the drug therapy (i.e., the primary drug), and the other type is not many physiologically active substances, and their roles include: filling action, adhesion, lubrication, and disintegration; occasionally, they also play a role in coloring, flavoring, and aesthetic effect; in pharmaceutics, these materials are commonly known as excipients (or excipients & Adjuvants). They divide the functions of various materials into four categories.

(A) a diluent (Diluents)

The main function of the diluent (or filler, Fil1ers) is to fill the volume or weight of the tablet to facilitate tabletting; steroid powder source commonly used fillers are starch, sugars, celluloses, and inorganic salts; depending on the tabletting process, preparation equipment, and other factors, the tablet diameter typically cannot be less than 6 mm, and it must weigh at least 100 mg.Without the inclusion of an appropriate filler, just a few milligrams or tens of milligrams of the primary medication can be converted into tablets. As a result, diluents played a more significant part in this process to aid in increasing the volume of the main medication's shaping function.

1, starch

Corn starch is more frequently used, it is very stable, most medications do not work, the cost is relatively low, moisture absorption, good appearance, and color. In the actual production, dextrin is frequently combined with powdered sugar because starch has a poor compressibility and will press out the tablet too loosely if used alone.

2, powdered sugar

Powdered sugar is crystalline sugar that has been dried and crushed at low temperatures to form a white powder. It has the advantage of strong adhesion and can be used to increase the hardness of the tablet, and the tablet surface is smooth and beautiful. The disadvantage is that hygroscopic long-term storage causes the tablet hardness to be too large, making disintegration or dissolution difficult. Except for buccal tablets or soluble tablets, it is generally not used alone, but often with dextrin.

3, dextrin

Dextrin starch hydrolyzate is a general word for intermediate products, and its chemical formula is (C6H10O5) n • XH2O, which dissolves slowly in cold water, is easily soluble in water, and is soluble in ethanol. Traditionally referred to as a high paste (high viscosity dextrin), which has strong adhesion, improper use will result in one-sided pitting, watermarks, or slow tablet disintegration or dissolution. In a similar vein, the content of If the determination is not sufficiently pulverized extraction will affect the measurement accuracy and reproducibility of the results, so it is rarely used alone as a filler dextrin heavy use, often combined with powdered sugar, starch.

4, lactose

Lactose is a great tablet filler that can be made from the whey of cows. It is more popular outside of the United States but is more expensive. Common crystalline lactose, also known as lactose hydrous, is non-hygroscopic, good at compressibility, stable, and most medications cannot tolerate chemical reactions. Lactose amorphous lactose, which is flowable and good at compressibility, is used in powder form for direct compression.

5, compressible starch

Pre-gelatinized starch, also known as pre-gelatinized starch (Pregelatinized starch), is a new excipient used in pharmaceutical products. China, Japan, the United States, and Britain have switched their Pharmacopoeia to reflect our country's successful development in 1988. Domestic products that are partially pregelatinized are compared favorably to overseas Colorcon's Starch RX1500 (sometimes referred to as entire pre-gelatinized starch). This substance has multiple uses, including as a filler. It also disintegrates more effectively and has good flowability, compressibility, self-lubricating and dry adhesion. Magnesium stearate should not be added in amounts greater than 0.5% when using powder for direct tableting to prevent softening effects.

6, microcrystalline cellulose

Microcrystalline cellulose (MCC) is made by partially hydrolyzing cellulose and then partially polymerizing smaller crystalline cellulose. It has good pressure, a strong binding force, is compressed into tablets with great hardness, and can be used as a "dry adhesive" in the form of a powder that can be compressed. Wholesale Steroids powder Products from abroad sold under the brand name Avicel and sized to a variety of various requirements. China has made extensive use of domestic microcrystalline cellulose, but the quality needs to be raised and the product selection needs to be expanded. Additionally, the optimum disintegrant level for tablets containing microcrystalline cellulose is 20%.

7, inorganic salts

Mostly due to a number of inorganic calcium salts, including calcium sulfate, calcium carbonate, calcium hydrogen phosphate, and pharmaceutically approved calcium carbonate (also known as precipitated calcium carbonate by the legal settlement). Where calcium sulfate is more frequently employed, its stable, flavorless and odorless, water-soluble nature makes it suitable with a wide range of medications. Tablets manufactured of smooth appearance, hardness, and good disintegration also prevent drug adsorption. Frequently used as calcium sulfate dihydrate in tablet excipients It should be mentioned that calcium sulfate can interfere with the absorption of some powerful medications (tetracyclines), thus it shouldn't be used at this time.

8, mannitol

It is more suitable for the preparation of chewable tablets, but the cost is a little high and is frequently paired with sucrose. Mannitol comes in granular or powder form, dissolves in the mouth, absorbs heat, giving there is a sense of cool, while both a certain sweetness in the mouth gives there is no gravel sense. making use of.

(B) an adhesive (Adhesives)

Certain drugs' powder already has a sticky consistency, so adding the right liquid can naturally cause viscosity to form. This liquid is then added as a wetting agent (moistening agent); other drugs' powder doesn't have a sticky or tacky consistency by itself; instead, they require the addition of starch and other viscous materials in order to bond them together.The aforementioned substances are sometimes referred to as wetting agents and sticky binders since they are crucial in holding almost all of the medication powder together.

1, distilled water

A humectant is distilled water. Since the substance tends to absorb water more quickly when applied. Since uneven wetting is more likely to occur, starch or ethanol should be used instead of low concentration to make up for these drawbacks.

2, ethanol

Ethanol acts as a humectant. It is possible to employ medications that are too viscous for water to dissolve them. The amount of wet sticky substance produced decreases with increasing ethanol concentration, therefore the alcohol concentration depends on the type of raw materials and is typically between 30% and 70%. It should be noted that Chinese medicine extract pills frequently employ ethanol as a wetting agent; therefore, it is important to work rapidly to prevent ethanol evaporation brought on by strong sticky clumps.

3, starch paste

The most widely used starch for tablet binders is starch slurry, which is most often employed at a concentration of 10%; if the material is less compressible, the concentration of starch can be appropriately increased to 8% to 15%. Instead, lowering the starch slurry's concentration—for example, using aluminum sheets with 5% starch as a binder—might be more suited. Boiling pulp and red pulp are two types of pulp that fall within the starch slurry system of law and can be used for its pasting capabilities. The phenomenon of the Noopept creation of a starch heated uniformly paste is referred to as "gelatinization" (Gelatinization); the temperature of fully gelatinized maize starch is 77 °C. Starch becomes significantly more viscous when it is gelatinized, making it useful as a tablet binder.In particular, the pulp is washed, starch is suspended in a small amount (1 to 1.5 times) of water, depending on the concentration and amount of the requirements into the boiling water, stirring continuously, and then the mixture is pasted together; for mashing, starch is suspended in the full amount of water, heated in a sandwich container, and stirred continuously (should not use direct fire heating, to avoid coking). The majority of this starch adhesive is made with starch because it is easily available, affordable, and has strong adherence, allowing users of the starch slurry to be granulated and fulfill the criteria for tableting.

4, sodium carboxymethyl cellulose

Insoluble in ethanol, chloroform, and other organic solvents coal, sodium carboxymethyl cellulose (CMC-Na) is a cellulose carboxymethyl ether compound. When dissolved in water, the initial particle surface puffing, and then soaked in water slowly to the inside of a transparent solution, but it requires a long time. Preferably heated to 60 °C to 70 °C after the initial puffing and swelling, can greatly speed up the dissolution process. The concentration employed as the binder is typically 1% to 2%. It is a powerful glue that is frequently used in medications that are difficult to compress, but it is important to consider whether the tablet hardness is too high or could lead to disintegration overrun.

5, hydroxypropyl cellulose

Its characteristics include being a white powder, soluble in cold water, swelling or gelling at 50 °C, and being soluble in methanol, ethanol, isopropanol, and propylene glycol. Hydroxypropyl cellulose (also known as HPC) is a derivative of hydroxypropyl cellulose and contains hydroxypropyl 53.4% to 77.5% (which is just hydroxypropyl content of 7% to 19% of the low- This product can be used as a powder for direct compression binders as well as wet granulation binders.

6, methyl cellulose, ethyl cellulose, and

Methyl and ethyl cellulose, also known as methyl and ethyl cellulose ether compounds, respectively include a methoxyl group or an ethoxyl group that ranges from 26.0% to 33.0% - 51.0% 44.0%. Among them, methyl cellulose has strong water solubility and acts as a binder by generating a viscous colloidal solution. It should be noted, however, that this product will precipitate when the concentration of sugar or electrolyte reaches a specific point. It should be noted that while ethanol and other organic solvents have greater solubility and stickiness depending on ethanol concentration, which can be used as a water-sensitive adhesive drug, ethanol cellulose is insoluble in water. The current viscous product is stronger and does not dissolve in gastrointestinal fluids, so when released as a tablet, it will break apart and have a drug-blocking effect.Currently, ethylcellulose is frequently utilized to prepare products with slow, controlled releases (controlled release film or matrix type).

7, hypromellose

Because it dissolves in cold water to form a viscous solution, hydroxypropyl methyl cellulose (also known as HPMC) is one of the most widely used film-coated materials. Its typical use as a binder ranges from 2% to 5%. In order to prepare an aqueous solution of HPMC, the best HPMC was first added to a total volume of hot water at a temperature of 1/5 to 3 l/3 (80 to 90 °C), where it was fully hydrated and dispersed. While the mixture cooled, it was constantly stirred in cold water until the desired volume was reached. This product is soluble in ethanol or a combination of 10% to 80% methanol and methylene chloride but not in alcohol, ether, or chloroform.

8, other binders

It should be noted that these very sticky adhesive, tablets made of hard, slightly too much will cause the tablet overrun to disintegrate. They are used in poorly compressible drugs along with 5% to 20% gelatin solution, 50% to 70% sucrose solution, and 3% to 5% polyvinyl pyrrolidone (PVP) aqueous or alcoholic solution.

(C) disintegrant (Disintegrants)

The general tablet disintegrating agents Vacuum pump should be given in addition to the delayed (controlled) release tablets as well as some particular purpose tablets, as gastrointestinal fluids swiftly break the tablet into small particles of substance.It is very advantageous for the tablet's main drug dissolution and absorption when the binding tablets can be disintegrated. This is because the binding tablets have a strong swelling property that allows them to be swollen. The tablet is disintegrated by breaking it into many small pieces from a single sheet of material.

1, dry starch

Dry starch is one of the most common disintegrating agents. It has a moisture content below 8%, is highly absorbent, and exhibits some degree of expansion, making it more suitable for water-insoluble or sparingly soluble drug tablets. However, soluble drugs have poor lipolysis due to the concentration difference in the dissolution of water soluble drugs, which prevents the tablet from easily penetrating the level of the solution inside the tablet through the outside water. In order to create the desired effect of disintegration, external, internal addition, or "internal and external addition" is typically used in production.In the so-called plus method, dried starch was added to dry granules before tableting so that tablet disintegration would take place between the particles. In the so-called adder method, starch was added during granulation so that tablet disintegration would take place inside the particles. To achieve a good disintegrating effect, usually plus disintegrating dosage 25% to 50% of the total amount of disintegrating agent, part of the increase in the starch and then applied a portion of the starch "internal and external addition" can occur in both the disintegration of tablets inside the particles took place between the particles,the entire weight of the tablet disintegrant is typically 5% to 20%; the dissolving dosage adds 75% to 50% of that total quantity.

2, sodium carboxymethyl starch

Sodium carboxymethyl starch (Carboxymethyl starch sodium, CMS-Na) is a white, amorphous powder with a strong water-swelling effect that can expand to 300 times its original volume after absorbing water (occasionally with a slight adhesive effect). It has good disintegrant properties and is inexpensive, typically costing between 1% and 6% (foreign products sold under the trade name "Primojel").

3, low-substituted hydroxypropylcellulose

In recent years, low-substituted hydroxypropyl cellulose (L-HPC) has been used more as a disintegrating agent. Due to its wide surface area and porosity, it has a good rate of water absorption, an expansion rate of 500% to 700% (substituent representing 10% to 15%), and finer particles following particle breakdown, which is advantageous for drug dissolution. often between 2% and 5%.

4, cross-linked polyethylene pyrrolidone

Crosslinked polyvinyl pyrrolidone, also known as cross-linked PVP, is a white, well-flowing powder that does not dissolve in water, organic solvents, acids, or alkalis but quickly swells in water without forming a viscous gel layer. Because of this, it has been used in the development of domestic products in countries like Britain and other European nations.

5, cross-linked sodium carboxymethyl cellulose

Cross-linked sodium carboxymethylcellulose (Croscarmellose sodium, CCNa) is a cross-linked carboxymethyl cellulose ether (about 70% of a sodium salt type carboxyl). Because of the crosslinks, it is insoluble in water but can absorb several times its weight in water and swell, giving it a better disintegration when combined with sodium carboxymethyl starch. However, when combined with dry starch, the disintegration will be reduced.

(D) a lubricant (Lubricants)

In pharmaceutics, the term "lubricant" refers to a wide range of substances, including glidants, anti-adherents, and (narrow) lubricants.①A glidant's purpose is to minimize friction between particles to increase the flow of a substance's powder;②Anti-adherents (Antiadherent) work to keep raw materials from sticking to the surface of the punch material;③ (narrow) lubricants, which really act as lubricants, work to lessen friction between the tablet and the material that lines the inside of the die hole. As a result, the ideal lubricant should fulfill the three functions of lubrication, anti-sticking, and glidants. However, the lubricants that are currently on the market frequently work well in one or two of these areas but have inconsistent performance in other areas. Materials are categorized in accordance with custom, and any effect not specifically mentioned above is referred to be lubricant.

1, magnesium stearate

The most extensively used hydrophobic lubricant is magnesium stearate, which is also easy to blend into particles and tablet after one-sided glossy look. Due to their hydrophobicity, excessive use might slow down the dissolving of the tablet, which Mexico raw steroids powder typically ranges from 0.1% to 1%. Additionally, certain antibiotics, acetic acid, and the majority of the drug's organic alkali salts in tablet form should not be used with this medication.

2, silica powder

An effective tablet glidant is silica powder (Aerosil), which can also be used as a powder for direct compression glidant. Its characteristics include being a white, odorless, and tasteless anhydrous powder with a wide surface area. However, due to its greater cost, domestic uses are still not sufficiently varied.

3, talc

Talc is primarily used as a glidant, and it can be recessed at the surface of the particles and filled up flat to reduce the roughness of the surface of the particles, the former to reduce friction between the particles, and to improve the flow of the particles to the object (it should be noted that because of the tabletting process, mechanical shock, it can separate from the particles). The typical dose is typically 0.1% to 3%, and at most not more than 5%.

4, hydrogenated vegetable oil

This product was spray-dried, and it has good performance in terms of lubricating. In order to promote uniform distribution, the application was dissolved in hexane or light liquid paraffin and then sprayed over the dry granules. (Terms of hexane solvent, following spray method utilizing hexane was eliminated under reduced pressure.)

5,Moonlight, polyethylene glycols, and magnesium alcohol

Each of these fits the mold of a water-soluble lubricant. The latter is the new water-based lubricant currently being developed. The former is mostly used polyethylene glycol 4000 and 6000 (Jieke dissolved in water), and the ensuing pill disintegration and dissolution is not affected to offer a clear solution.

In addition to these four ingredients, the tablet may also contain excipients such as coloring, flavoring, and other ingredients to enhance taste and appearance. However, any additional ingredients must adhere to all medical requirements and not interact negatively with the primary medication or prevent its absorption. As of right now, it is known that lactose can lessen the effects of pentobarbital, calcium can impact how well tetracycline medications are absorbed, and spironolactone absorption of starch can delay the absorption of sodium salicylate. Therefore, the selection of the right accessories should be based on the physicochemical and biological characteristics of the primary drug, in combination with the unique production method, through in vivo investigations.